Stuart McAvoy, Global Director of Supply Chain Optimization and Sustainability, UPS

For decades, supply chain specialists focused on wringing every ounce of value or saving the most amount of time by optimizing the movement of goods. At the same time, sustainability specialists focused on reducing carbon footprint and environmental impact. In some cases, these two very different goals were aligned. But all too often, the objectives were pursued independently of one another.

For decades, supply chain specialists focused on wringing every ounce of value or saving the most amount of time by optimizing the movement of goods. At the same time, sustainability specialists focused on reducing carbon footprint and environmental impact. In some cases, these two very different goals were aligned. But all too often, the objectives were pursued independently of one another.

The situation frequently bred frustration among both supply chain and environmental sustainability experts. Those days are thankfully fading away. Perpetual harmony is on the horizon.

The one element that was so often missing is surprisingly simple. Collaboration. At UPS, we live by the adage that the greenest mile driven is the one you don’t drive at all. It’s also the most profitable mile.

That’s why we meticulously study techniques and explore technologies that minimize the number of miles traveled at every point in the supply chain. When a mile must be traveled, make the most of it through a combination of streamlined travel patterns, multi-modal transportation options, and alternative fuel and advanced technology vehicles.

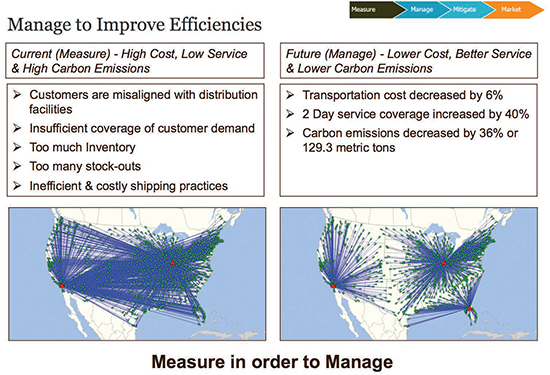

For example, by increasing its warehouses from two to three, one company decreased its carbon footprint more than 30 percent, improved its customer service by 40 percent, and decreased its transportation costs by six percent.

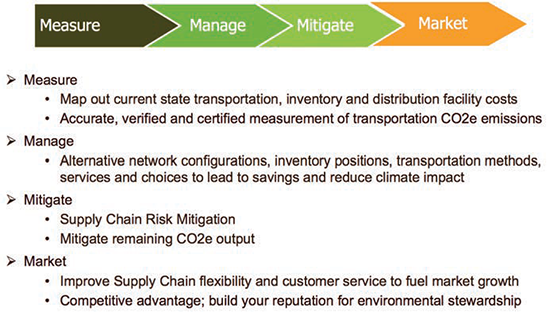

Is increasing assets counterintuitive to reducing environmental impact? Sometimes, yes. The revelation lies in a company’s supply chain analytics. Where are the manufacturing, distribution and retail points? What volume of products are transported at what intervals? What are the time in transit constraints and why? How does seasonality impact the business, both from the company’s suppliers and outside industries?

When a 360-degree view of a business’ existing infrastructure and planned growth is developed, a road map materializes that reveals where business and environmental efficiencies converge.

This is how many companies are now improving customer service and the bottom line while, at the same time, reducing greenhouse gas emissions. One company, for example, takes the equivalent of nearly 30 passenger vehicles off the road and keeps 40 tons of waste out of landfills annually by taking this approach.

Right now, the retail and transportation industries are jointly facing a tremendous challenge. How do we continue to meet online shopping demand while mitigating the rising financial and environmental costs of residential deliveries?

For our part, UPS is meeting this challenge head-on by acting as strategic counsel to our customers and investing in environmentally sustainable business assets.

We have a team of experts deployed around the world who design and implement supply chain optimization strategies that enhance customer service, improve financial results, and decrease environmental impact. The example mentioned above is one of our many case studies.

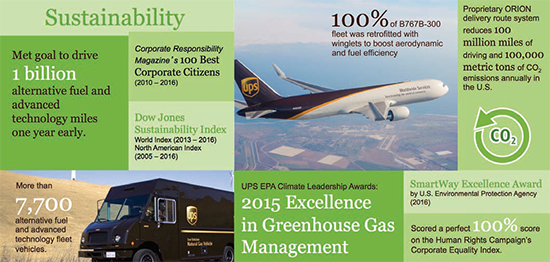

UPS’s fleet of more than 8,100 alternative fuel and advanced technology vehicles met our goal of driving more than 1 billion miles a full year early in August 2016. We developed UPS’s proprietary ORION (On-Road Integrated Optimization and Navigation) route optimization software to eliminate 100 million miles and 100,000 metric tons of CO2 emissions each year. And we’re testing non-traditional vehicles, such as the eBike in the U.S. and Cargo Cruiser in Europe, that challenge urban package delivery models.

By combining more efficient supply chains with transportation infrastructure that reduce environmental impact, companies receive more than public accolades. It’s good for the bottom line.

Environmental sustainability no longer has to ‘cost’ a business. Modern supply chain strategies are proven to enhance a company’s profitability, customer experience, and environmental stewardship. That’s a road map worth following.

Stuart McAvoy is the Global Director of Supply Chain Optimization and Sustainability at UPS, where he manages global resources that model and optimize supply chain solutions for UPS Customers. Stuart and his team develop solutions that utilize all modes of transportation and models the Carbon Output impact of supply chains to negate Carbon Output.